Comparison of Sulfur Concrete, Cement Concrete and Cement-Sulfur Concrete and their Properties and Application

Ali Ghasemi Khademi1 * and Hooshyar Imani Kala Sar2

1

Civil Engineering graduate student at Mohaghegh Ardabili-iran University,

Iran

2

Assistant Professor and faculty member of Mohaghegh Ardabili-iran University,

Iran

DOI: http://dx.doi.org/10.12944/CWE.10.Special-Issue1.26

One of the applications of sulfur in construction and industry is producing sulfur concrete. Sulfur concrete has charming features and many properties such as high strength, corrosion resistance, mechanical strength, impermeability, recyclability and rapid hardening that have caused much interest in using it. It can be used in dam building, construction of sewer pipes, irrigation canals, concrete piles, piers, beach walls and etc , so that a greater proportion of cement produced in the country would be used in construction because generally sulfur concrete cannot be used instead of cement concrete unless in areas with medium and low structural importance or when there is no possibility of using concrete cement. Results obtained in this study indicate that sulfur concrete with the additional stuff, cover cement concrete with sulfur-modification, sulfur concrete containing fiber, sulfur concrete with electrolytic residual and sulfur concrete with fly ash, depending on the combination of resistance in most cases, have equal to or higher resistance than conventional sulfur and cement concrete; it is also clarified that sulfur concrete with fly ash has higher pressure resistance than the other compositions.

Copy the following to cite this article:

Khademi A. G, Sar H. I. K. Comparison of Sulfur Concrete, Cement Concrete and Cement-Sulfur Concrete and their Properties and Application. Special Issue of Curr World Environ 2015;10(Special Issue May 2015). DOI:http://dx.doi.org/10.12944/CWE.10.Special-Issue1.26

Copy the following to cite this URL:

Khademi A. G, Sar H. I. K. Comparison of Sulfur Concrete, Cement Concrete and Cement-Sulfur Concrete and their Properties and Application. Special Issue of Curr World Environ 2015;10(Special Issue May 2015). Available from: http://www.cwejournal.org/?p=987

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2015-02-02 |

|---|---|

| Accepted: | 2015-04-01 |

Introduction

The availability of sulfur in the last few decades has increased significantly in many countries.Large amounts of sulfur is obtained through refining crude oil and natural gas, sulfur mines, refining sour gas, refining copper from mines, coal refining and even removal of hydrogen sulfide from crude oil and natural gas (Gracia el al., 2004),(Behfarnia el al., 2010),(Kalb el al., 2004) and since a ton of cement generates about one ton of carbon dioxide, producing sulfur concrete reduces global warming and is an effective solution to environmental problems associated with the use of effective Of sulfur (Robert el al., 1974). Concrete sulfur has many applications in industry among which we can name prefabricated building elements such as sidewalks and road blocks, construction of drainage and sewage facilities, basic coverage foundation, making the acid tanks,manufacturing and repairing concrete platforms and etc.(Gracia el al., 2004),(Robert el al., 1974), (Naufal Rizwan el al., 2014),(Vedalakshmi el al., 1990),(Orlowshki el al., 2004). According to the present annual production of 80 million tons of cement in the country and it is expected to increase to 120 million tons in the coming years, also cement producers "interest" in exporting, increasing capacity in this section, adjusting the usage amount and optimization techniques are among the basic ways out of the crisis in this industry, between which the use of sulfur concrete is a useful and effective solution. Sulfur concrete is not a new substance in industry but using molten sulfur as a binder goes back to 17th century, this material was used for fixing metal in the ore (in the dock and anchor) today this method is used both in England and America.

In 1859, Mr. Wright presented an invention for introducing the cement properties of sulfur, during this period the cost of sulfur was very high, but 60 years after the above date, almost no research was carried out on sulfur; during World War I there was lots of demand for sulfur and new ways were suggested to use it. In 1921 a study was conducted on the use of sulfur for production of building materials and a mortar with 40% sulfur, which had a very high resistance in acidic environment and had good mechanical properties was obtained, the mortar proposed in this case faced with reduction of bending strength with the temperature changes, the chemical properties of sulfur was modified with a sulfur multi atom alkene. But in the 1940, the above mortar has been developed by additives and due to the increased viscosity of the material, industrial acceptance and use of this material raised and it was very suitable and proper for the construction in acidic environment. In 1960, the concentration was on viscosity of this material and in 1970 durability of it, was focused on and successful projects were carried out by this concrete in North America and it was used in the construction of the highway and industrial buildings of the America (Gracia el al., 2004).Still a great deal of research and innovation are being conducted in many countries including America, Canada, Poland and Russia and building materials such as sulfur concrete and sulfur asphalt have been noted more because these materials are environmentally friendly and cost effective.(Ciak el al., 2013)

Below we will study the tests carried out on this matter and the results of these experiments will be discussed.

Discussion

There are two ways to use sulfur cement in the preparation of concrete: a) first the sulfur cement should be warmed after reaching molten status it is poured into the mixture of heated sand. b) Sulfur cement will be changed in to the form of the powder and after heating the sand they will be mixed in the mixer so that after getting the needed temperature from the mixture the powder will be turned into the molten and will form sulfur concrete. In all the below tests the first method has been used for producing sulfur concrete.

Sulfur concrete consists of a mixture of aggregates, sulfur, filler and additives (for preserving elastic property of concrete and preventing loss of resistance, an additional matter is used like SMZ, SRX, DCPD)

Experiments carried out on sulfur concrete examples:

1.Ordinary sulfur concrete without additives (18% sulfur cement, aggregates and filler) (Behfarnia el al., 2010)Compression Strength Test

Tested sulfur concrete has compression strength of 20 MPa, and after 14 days it reaches the strength of 25 MPa, which has a growth rate of 25 percent, but after this time the compressive strength of sulfur comes down even less than the resistance of 14 days and gets a growth rate of 12.5 percent compared to the resistance of one day.

2.The sulfur concrete with SMZ additive (3.3% of the whole added material is intended SMZ) (Behfarnia el al., 2010)

compression Strength Test

The results show that the compressive strength of sulfur concrete with SMZ additive moved from the strength of 25 MPa a day with 10% growing rate to 27.5 MPa in 14 days, also this concrete reached the resistance of 33MPa in 28 days which had a growing rate of 32% compared to the resistance of one day.

3.Sulfur concrete with Dicyclopentadiene additive (DCPD) (one percentage of the materials considered to be DCPD) (Behfarnia el al., 2010)

Compression Strength Test

The results obtained indicate that the compressive strength was 25 MPa on the first day and on the fourth day it reached 36 MPa, which represents growth of 44 percent and on 28th day the strength was 42 MPa, which represents growth of 68 percent compared to The resistance of day one.

1-2-3- b) testing examples of sulfur concrete against sulfuric acid

|

Fig. 1: Results of sulfur concrete resistance test against acid Click here to View figure |

As you can see, these examples reacted very well against acid and virtually show no corrosion in the 4-weeks of immersion in 6.6 molar sulfuric acid.

1-2-3- b) sulfur concrete samples test against sodium hydroxide

|

Fig. 2: The results of the sulfur concrete strength test against sodium hydroxide Click here to View figure |

Above examples suffer from corrosion in base environment and only sulfur concrete with Dicyclopentadiene resisted against corrosion after 4 weeks of immersion in base soluble and only lost 7.8% of its weight.

Ratio of sand to the aggregate is 45%, air 5% and ratio of water to cement and sulfur is variable ( 5, 7.5 and 10 percent)

Mix design Process

|

Fig. 3: Mix design of the covering cement concrete with modified sulfur Click here to View figure |

Compression Strength Test

|

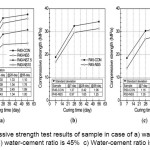

Fig. 4: compressive strength test results of sample in case of a) water-cement ratio is 40% b) water-cement ratio is 45% c) Water-cement ratio is 50% Click here to View figure |

Compressive strength of samples has inverse relationship with water cement ratio and compressive strength decreased with increasing amounts of sulfur and samples' resistance becomes less than normal sulfur samples.

Flexural Strength Test

|

Fig. 5: Flexural strength test results of sample in case of a) water-cement ratio is 40% b) water-cement ratio is 45% c) Water-cement ratio is 50% Click here to View figure |

Flexural strength of samples up to 5% sulfur coating concrete has no effect on flexural strength of concrete, but for the sulfur content of more than 7. 5 percent causes quick decrease of flexural strength.

Testing the Samples' Resistance Against Molten and Frigidity

Weight loss of typical samples of sulfur concrete was almost two times more than sulfur coated samples (due to pores in conventional sulfur concrete and water penetration).

Testing Resistance Against Sulfuric Acid

|

Fig. 6: strength test results of sample against sulfuric acid a) water-cement ratio is 40% b) water-cement ratio is 45% c) Water-cement ratio is 50% Click here to View figure |

Weight changes in conventional sulfur concrete samples are more than sulfur coating cement concrete samples.

Glass fiber in sulfur concrete has significant impact on the risistance of sulfur concrete and it has more resistance than conventional sulfur concrete samples.

6.Sulfur concrete with electrolytic manganese residual (as a filler) (Yang el al., 2014)Compression Strength Test

The samples with 45% sulfur and electrolytic manganese residue of 35% and 20% sand have high pressure resistance around 63. 01 MPa.

Flexural Strength Test

Samples with 45% sulfur and 30% electrolytic manganese residue and 25% sand have a high bending strength of about 9. 47 MPa.

- Sulfur concrete with fly ash (40% coarse, 32 % grained, 22 percent sulfur and 6 percent fly ash) (Shin el al., 2014)

Replacement of some modified sulfur with fly ash increases the compressive strength and tensile strength and fill the pores of the concrete caused by fly ash and increases the concrete density and hardness and reduces the modulus of elasticity and coefficient of thermal expansion of sulfur concrete.

- Recycled aggregate concrete sulfur (40% coarse, 32% grained, 22% sulfur and 6% recycled aggregates ) (Shin el al., 2014)

The use of recycled aggregates in concrete reduces sulfur concrete compressive and tensile strength and decreases the hardness and modulus of elasticity of concrete and increases the coefficient of thermal expansion.

- Sulfur concrete with fly ash and recycled aggregate (40% coarse, 32% grained, 22% sulfur and 6% fly ash and recycled aggregates) (Shin el al., 2014)

Have higher compression resistance compared to conventional sulfur concrete samples with natural aggregates and without fly ash.

- Concrete sulfur in water (Yahia el al., 1994)

Putting sulfur concrete in the water reduces the strength of the concrete, the maximum resistance reduction occurs during the 3 days of immersion of the samples in the water and sulfur concrete samples' resistance decreases for 50%.

Table1: The average results of tests carried out on samples of sulfur concrete and cement concrete

| Cement concrete | Sulfur concrete | Unit | Properties |

| 2200 | 2400 | Kg/ | Density |

| 15-60 | 60-115 | MPa | Compressive strength |

| 6-7 | 10-16 | MPa | Bending strength |

| 25-28 | 35-50 | GPa | Modulus of elasticity |

| 0.6 | 0.5-1 | mm/m | Contraction |

| 9-15 | 1-4 | % | Porosity |

| Medium | High | - | Corrosive durability in aggressive surroundings |

| Medium | High | - | Frost resistance |

| 48 | 0.1-0.4 | Hour | Minimal period for forming an element |

| 28 days | 2-24 | Hour | Minimal period for nominal strength |

conclusion

The following table shows the average results of tests carried out on samples of sulfur concrete and cement concrete. (Ciak el al., 2013)

In experiments on sulfur concrete samples, the effect of additive on increasing compressive strength of sulfur concrete and preventing it from the loss was apparent, and preference of Dicyclopentadiene over SMZ was clear. (Behfarnia el al., 2010)

- Portland cement concrete will have severe corrosion in acidic environment while sulfur concrete has very good resistance against acidic environment and this concrete will almost have no corrosion in Acid but samples of sulfur concrete with Dicyclopentadiene show less weight loss than the other samples. (Behfarnia el al., 2010)

- The conventional sulfur concrete collapses after one month immersion in the sodium hydroxide solution and loses half its weight but sulfur concrete with DCPD shows better resistance than other samples and lost only 7.8% of its weight during the 4-week immersion in base solution. (Behfarnia el al., 2010)

- The compressive strength of cement concrete samples with modified sulfur is always less than the control samples with typical size; flexural strength of the samples with 5% sulfur content is approximately equal to bending strength of normal control samples with conventional aggregation, but more than 5% sulfur reduces the bending strength of samples.Melting and freezing resistance of these concretes are almost double the normal sulfur concrete samples and weight changes of these samples in acidic environments is always less than typical sulfur concrete samples. (Lee el al., 2014)

- The composition of sulfur concrete with fibers and sulfur concrete mixture with residual electrolytic manganese increases the strength of sulfur concrete while the mixture of sulfur concrete with residual electrolytic manganese, depending on the strength of concrete mix design that has been mentioned in the article, will get the resistance to 63.01 Mpa and bending strength to 9.47 Mpa. (Margal el al., 2014),(Yang el al., 2014)

- The composition of fly ash with sulfur concrete with mix design, that has been pointed out in the discussion, causes 39 percent increase in compression strength and 83 percent increase in tensile strength and will reach compression resistance of 88 Mpa while the sample of sulfur concrete with recycled aggregate reduce compression resistance up to 13% and tensile strength of concrete for 33 percent. (Shin el al., 2014)

- It is clear from the results of experiments carried out, sulfur concrete samples with fly ash with a clear mixture design, have higher compression strength than other combinations of sulfur concrete and cement concrete, and they have two times more strength than sulfur concrete samples with DCPD and approximately 1.5 times more strength than sulfur concrete samples with residual electrolyte.

- The compressive strength reduction of the samples depending on the kind of concrete aggregate and water temperature in the range of 42-75%, which had the most resistance decrease of samples related to basalt aggregates immersed in water at 20 degrees Celsius. (Yahia el al., 1994)

References

- Behfarnia, Bokaie Jazee, M. Laboratory study of sulfur concrete and its features. Fifth National Congress on Civil Engineering. May 4-6, Mashhad Iran (2010).

- Ciak, N.;Harasymiuk, J.Sulphur concrete’s technology and its application to the building industry.Technical Sciences,16(4),323-331(2013).

- Gracia, V. Vàzquez, E. Carmona, S. Utilization of by-produced sulfur for the manufacture of unmodified sulfur concrete. International RILEM Conference on the Use of Recycled Materials in Buildings and Structures.November 8-11,Barcelona (2004).

- Kalb, P.vagin, S. Beall, P.Levintov, B. Sustainable development in Kazakhstan using oil and gas production by-product sulfur for cost-effective secondary end-use products. rewash 2004 global symposium on recycling waste treatment and clean technology.september.Madrid(2004).

- Lee, S.; Hong, K.;Park, J.;Ko, J. Influence of aggregate coated with modified sulfur on the properties of cement concrete.Materials,7(6), 4739-4754(2014).

- Margal, I.;Brajchenko, S.;Effect of parameter of fiber indispersed reinforcement of concrete and sulfur concretes.SCTP,781(3),111-115(2014).

- Naufal rizwan, P.;Dhiwagar Maria Jesuraj, S.;Vipin, V.;Anbuvel V.;Prabhakaran,S. Feasibility and application of sulfur in concrete structures.IJERT, 3(8), 108-111(2014).

- Orlowski, J.;Leszczewski, M.;Margal, I. Stability of polymer sulfur concrete with steel reinforcement.Technical Sciences, 7(1),101-108(2004).

- Robert, ; Alan, H.; Vroom, A.; Michael, A.Sulfur concrete-a new construction material.PCI journal, p. 86-95(1974).

- Shin, M,;Kim, K.;Gwon, S.;Cha, S. Durability of sustainable sulfur concrete with fly ash and recycled aggregate against chemical and weathering environments. Construction and building materials, 69(1),167-176(2014).

- Vedalakshmi,B.;Parthiban,G.;Rengaswamy,N.;Srinivasan,S.;Balakrishnan,K.Sulfur concrete for repair works.Bulletin of electrochemistry , 6(2),211-212(1990).

- Yahia, ;Al Qudah, M. The combined effect of water and temperature on the strength of sulfur concrete.Cement and concrete research, 24(1),165-175(1994).

- Yang, C.; Lv, X.;Tian, X.;Wang, Y.;Komarneni, S.An investigation on the use of electrolytic manganese residue as filler in sulfur concrete.Construction and building materials, 73(1), 305-310(2014).